Sliding doors 2

Showing all 5 results

Showing all 5 results

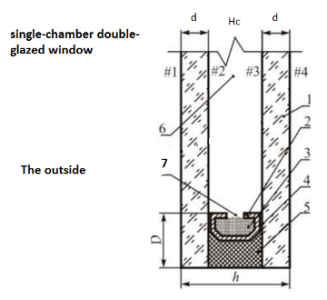

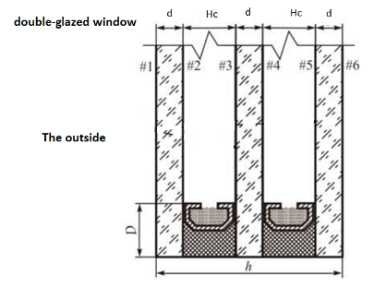

Glass unit

1 – glass; 2 – spacer; 3 – desiccant silica gel; 4 – primary sealant; 5 – secondary sealant; 6 – air chamber; 7 – dehydration holes; d – glass thickness; h – double-glazed units thickness; Hc – distance between panes; D – sealing depth; #1-#6 – numbering of glass surfaces in the design of double-glazed units

To improve the characteristics of double-glazed windows, energy-saving glass with various types of spraying is used.

K-glass (hard) – float glass is covered with asphalt. Sputtering glass on the surface of the metal oxide improves its energy saving properties, while reducing emissivity. During the production of float glass, when it is still hot, is deposited by pyrolysis of a thin metal oxide film. Due to the interaction of glass and metal oxide atoms is formed resistant coating, which not afraid of any mechanical damage. To further enhance the heat-shielding characteristics of the K-quenched glass and laminated.

I-glass (soft) is a new generation of glass in the glass industry. It is very similar to the K-glass, but has a higher level of core indicators. In the float glass is applied in two layers of low emissivity metal oxide deposition. This process occurs with the installation of the vacuum magnetron sputtering equipment. This method of coating deposition is called “soft” or Double Low-E.

Multifunction glazing (Mult), when the external glass combines the properties of the sun and energy saving, have become a reality.

In the multi glass surface metal coating is applied, the only difference from the AND Glass is not superimposed in one and in several layers. And each of the next layer of molecules lie crosswise with the molecules of the previous one. This ensures reflection of heat into the room in winter and in summer – outside.

Numbers of glass surfaces in the design of double-glazed windows for different types of coating.

| Visible Light

(EN 410-2011) |

Thermal properties (EN 673-2011) | Solar energy

(EN 410-2011) |

|

| 4 Float – 16 – 4 Low-E #3 | 80,0 | 1,360 | 62,6 |

| 4 Mult #2 – 16 – 4 Float – 16 – 4 Low-E #5 | 62,7 | 0,728 | 43,9 |

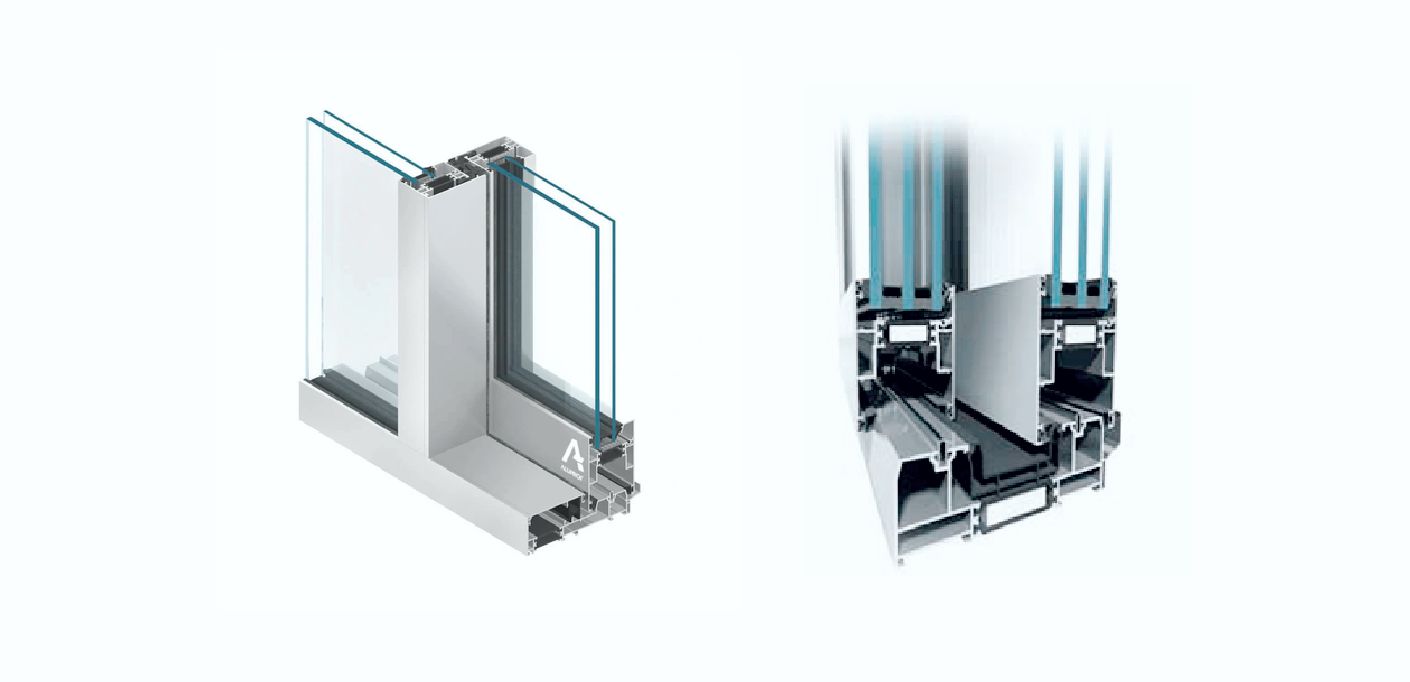

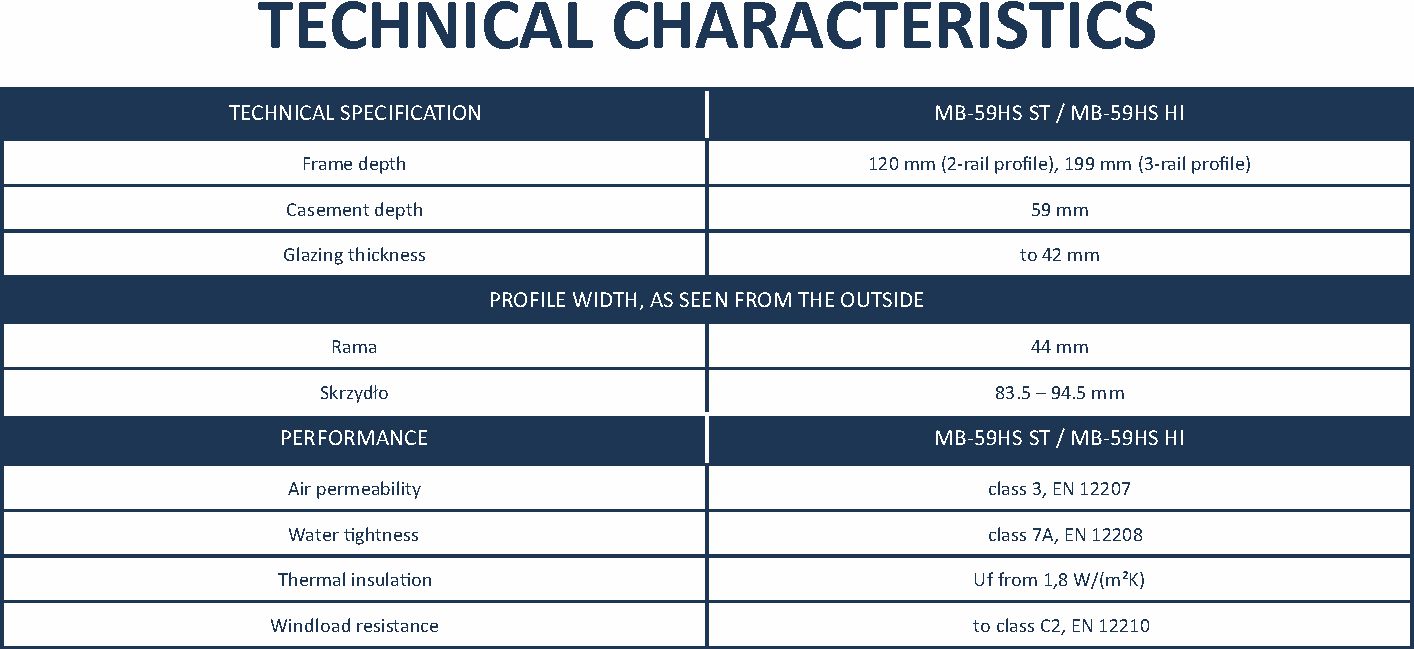

MB-59HS gives you great possibilities in applications of lift & slide doors, and is the optimized solutions in terms of construction and dimensions of its profiles and frames. With its high thermal and sound insulation, combined with excellent water and air tightness, MB-59HS meets all the requirements for energy conservation and environmental protection.

| 2000 | 2100 | 2200 | 2300 | 2400 | 2500 | 2600 | 2700 | 2800 | 2900 | 3000 | 3100 | |

| 2000 | 2103,82 | 2125,84 | 2146,94 | 2167,81 | 2188,59 | 2209,37 | 2231,17 | 2253,51 | 2274,28 | 2295,16 | 2315,94 | 2340,46 |

| 2100 | 2131,80 | 2153,82 | 2174,92 | 2195,79 | 2216,57 | 2237,35 | 2259,15 | 2281,49 | 2302,27 | 2323,14 | 2343,92 | 2368,44 |

| 2200 | 2159,52 | 2181,54 | 2202,63 | 2223,51 | 2244,28 | 2265,06 | 2286,87 | 2309,21 | 2329,98 | 2350,86 | 2371,63 | 2396,16 |

| 2300 | 1640,42 | 1662,45 | 1683,54 | 1704,41 | 1725,19 | 1745,97 | 1767,77 | 1790,11 | 1810,89 | 1831,76 | 1852,54 | 1873,32 |

| 2400 | 1668,40 | 1690,43 | 1711,52 | 1732,39 | 1753,17 | 1773,95 | 1795,75 | 1818,09 | 1838,87 | 1859,74 | 1880,52 | 1901,30 |

| 2500 | 1696,12 | 1718,14 | 1739,24 | 1760,11 | 1780,89 | 1801,67 | 1823,47 | 1845,81 | 1866,59 | 1887,46 | 1908,24 | 1929,02 |

| 2600 | 1723,84 | 1745,86 | 1766,96 | 1787,83 | 1808,61 | 1829,38 | 1851,19 | 1873,52 | 1894,30 | 1915,18 | 1935,96 | 1956,73 |

| 2700 | 1751,82 | 1773,84 | 1794,93 | 1815,81 | 1836,59 | 1857,36 | 1879,17 | 1901,51 | 1922,29 | 1943,16 | 1963,94 | 1984,71 |